PROJECT SHOW

荣誉资质

Hot rolling

- Categories:Solution field

- Author:

- Origin:

- Time of issue:2019-04-19 10:10

- Views:

Hot rolling

- Categories:Solution field

- Author:

- Origin:

- Time of issue:2019-04-19 10:10

- Views:

Summary

The rolling temperature measurement system is based on a colorimetric thermometer and data acquisition software.

The temperature in hot rolling mainly indicates the furnace temperature, the rolling temperature, and the finishing temperature. These temperatures have a direct effect on the deformation resistance of the metal in each frame, the rolling pressure, the metallurgical structure of the finished product, the grain size, the mechanical properties and the surface state of the finished product.

Temperature change during the ligation process (taking steel plate rolling as an example):

Release temperature: 1100-1250℃

Rolling temperature: 1000-1100℃

Final rolling temperature: 600-650℃

Aims

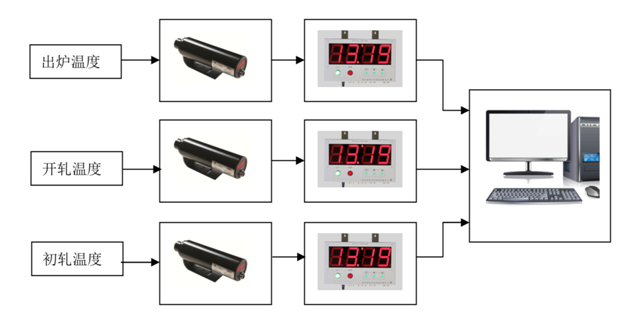

Real-time online monitoring, display, and data storage for furnace temperature, rolling temperature, and final rolling temperature.

Solution

System composition:

The system includes: 3 colorimetric thermometers, 3 large screen displays, 3 water-cooled-fengshui sweeps, 1 A/D capture card, and 1 set of software.

This system does not include a mounting bracket.

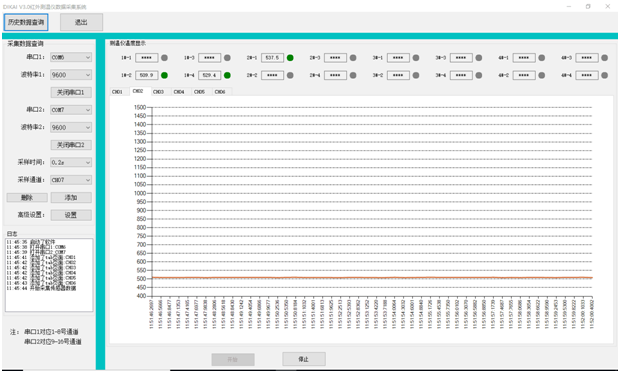

Software main interface:

Introduction to the system core components

Introduction to DIT Colorimetric Thermometer

1, Overview

The DIT series of thermometers use a double color temperature measurement method, that is, the ratio of the energy of two infrared bands radiated by the target object to determine the temperature of the object to be measured. Since the measurement results depend on the ratio of the radiation doses of the two bands, the partial loss of the radiant energy has no effect on the measurement results. The double color thermometer can overcome the measurement error caused by the transmission medium with dust, smoke, moisture, partial occlusion of the field of view, or measurement of the attenuation of the radiation caused by the change of distance. Suitable for relatively harsh temperature measurement sites.

The DIT double color infrared thermometer is equipped with a visual sighting system and a measured value display and parameter setting system. The visual aiming is convenient for the user to install the instrument, and the visual system can be used to intuitively understand the real-time working condition of the heating body; the measured value display and parameter setting system can display the current measured value in real time, and the display window can be freely set with the user parameter by the button. The operating mode of the thermometer can be defined by user parameters, so double color measurement and monochrome measurement can be switched. The instrument is easy to operate.

In the process of using the infrared thermometer, the measurement error caused by the following reasons is generally encountered: 1. The surface state of the material oxidation changes, or the oxide and the parent material crack, causing a large measurement error; 2. Due to the material itself The emissivity is low, causing measurement errors; 3. Measurement errors due to poor measurement environment. The double color temperature measurement method can solve these measurement problems well.

2, Main technical parameters:

2.1, Measurement range: 600-1400 ℃

2.2, Basic error: 0.5 (±0.5% FS)

2.3, Repeatability: 0.2%

2.4, Distance coefficient: 280:1

2.5, Measuring distance: 0.56m-∞

2.6, Measurable minimum target: φ2mm (560mm)

2.7, Response time: <10ms

2.8, Slope compensation: 0.850-1.150

2.9, Emissivity: 0.10-1.00

2.10, Response wavelength range:

Double colors: 0.8-1.1μm & 0.4-1.1μm

Single color: 0.4-1.1μm

2.11, Temperature resolution: 0.5℃

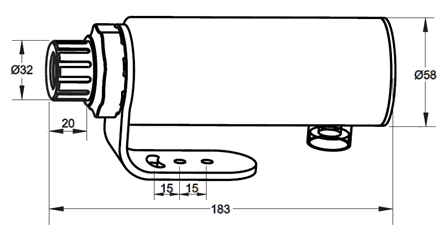

2.12,Probe size: φ58×183mm

2.13, Analog output: 4-20mA

2.14, Communication interface: RS485

2.15, Working power: 24VDC

2.16, Power: <1.2W

2.17, Working environment: 0-60℃, relative humidity 10-95% (no condensation 25-45℃)

2.18, Use standard: colorimetric thermometer industry standard JB/T 9240-1999

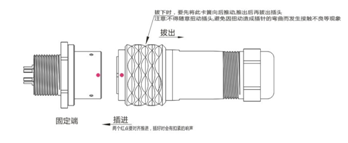

3, structure

3.1 DIT double color thermometer appearance structure

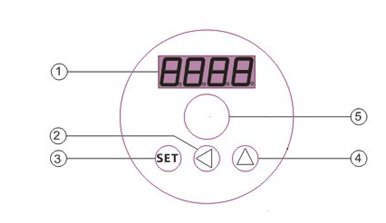

3.2 DIT double color thermometer panel description

3.2.1, Measurement value display and parameter setting window.

3.2.2, Decimal point shift key, each time the key is pressed, the decimal point moves by one digit, and the decimal point can be edited.

3.2.3, Parameter setting button, press and hold the button for 5s to enter the parameter setting state.

3.2.4, Number plus key, press this key once, the digit of the decimal point is increased by 1.

3.2.5, Visual sighting window, can be adjusted with the objective lens to clearly aim and observe the target.

4, DIT double color thermometer selection table

|

型号 |

Explication |

Remark |

|

|

DIT |

Double color thermometer |

English abbreviations |

|

|

Range |

611 |

600~1400℃ |

Customize range according to the request |

|

612 |

800~1800℃ |

||

|

613 |

1000~3000℃ |

||

|

Output |

I |

0-20mA |

Customize output according to the request |

|

4~20mA |

|||

|

V |

0~5VDC |

||

|

Communicated interface |

C |

RS485 |

DKBUS485/MODELBUS |

|

Aim |

Visual aiming |

Visual aiming |

|

5, Use

5.1 installation

According to the installation bracket diagram, the infrared thermometer is installed at an installation temperature of less than 65 °C with M6 or 1/4 inch screws. The position of the temperature measurement can be adjusted by the fan-shaped hole to achieve accurate aiming.

Installation of curved plate

5.2, Lead line definition

|

Connector lead pin |

Color of wire |

Derivative wire defined |

|

Six core wire |

||

|

1 |

Red |

24V |

|

2 |

Blue |

0V |

|

3 |

Black |

-OUT |

|

4 |

Yellow |

+ OUT |

|

5 |

Green |

A |

|

6 |

White |

B |

The shielded wire is connected to the sensor housing and can be connected to the user equipment. When it is not possible to connect, it can be connected to the power ground.

5.3, Wiring and precautions

5.4, Output selection

Analog signal output: 0-20mA, 4-20mA and 0-5VDC, the user can freely set according to the input specifications of the display control system.

RS485, there are two kinds of communication protocols available. When DKBUS485 is selected, it can be matched with the company's data acquisition software to realize real-time measurement of measurement data.

The serial port is a simplex transmission mode, the DKBUS485 protocol is selected, the communication rate is 9600 bit, the MODEBUS protocol is selected, and the communication rate can be set.

For process control or remote communication, an RS485◇RS232 converter is required to connect to the computer.

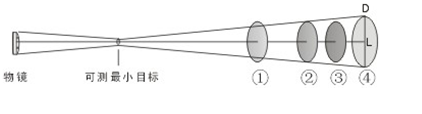

5.5, Aiming and distance coefficient

5.5.1, Distance coefficient

Distance coefficient: the optical resolution, the ratio of the distance D from the objective lens to the target to be measured and the effective diameter S of the measurable target, D:S.

The DIT double color thermometer has a distance coefficient of D: S = 280:1, a minimum target diameter of 2 mm, and a probe-to-measurable minimum target distance of 560 mm.

In the double color measurement mode, the measurement distance change and the inability to fill the field of view measurement have little effect on the accuracy. The following description is mainly for the monochrome measurement mode.

Distance coefficient diagram

1 The field of view of the infrared thermometer is smaller than the effective diameter of the target to be measured, and the measured temperature is the target accurate temperature. It is recommended to use this temperature measurement scheme without special installation requirements.

2 The target is filled with the field of view of the infrared thermometer. The measured temperature is the exact temperature of the target, but it imposes high requirements on the installation, especially the aiming aspect.

3 The measured target is not filled with the infrared thermometer field of view, and the measured temperature is lower than the actual temperature.

4 Effective field of view of the infrared thermometer.

5.5.2 Aiming

The DIT double color thermometer uses a visual aiming method. In the aiming system, the reticle is "¤" shaped, and when the target object is at the center of the mark, the thermometer is aimed at the object to be measured.

Scan the QR code to read on your phone

400-811-6877

Tel:027-8750 9386 027-8750 9105

Add:Dingye building C block, International Enterprise Center, Optics Valley Avenue, Wuhan China

Fax:027-87745185

Mail:dkoe@chinadikai.com