Infrared pyrometer is a non-contact type temperature measuring instrument. Unlike traditional thermocouples which use thermal equilibrium to measure temperature, infrared pyrometers need to receive infrared radiation energy or energy-related information of the target object to achieve temperature measurement. Therefore, the material characteristics, shapes and instrument installation environment will affect the accuracy of measurement.

How to choose the correct infrared pyrometer to achieve accurate measurement? For different industries, measured targets and using environments, Dikai Optoelectronics has developed suitable infrared pyrometers that can adapt to various temperature measurement applications.

The detection wavelength is the most critical parameter for environment where the infrared pyrometer is used. The short-wave pyrometers developed by Dikai are suitable for temperature measurement of all targets from 100-3500°C.

Below is an example of gas heating device:

The parameters of most single-wave infrared pyrometers (1-color pyrometers) are almost the same, especially the measuring range. Other parameters of the pyrometer with the same range are different, especially the response wavelength parameter. Infrared pyrometers of the same temperature range with different response wavelengths are suitable for different measurement targets. The infrared pyrometer can pass through some interfering medium by correct wavelength selection, to measure the true temperature of the target being measured. For example, infrared pyrometers can pass through steam, flame and combustion gas to measure the true temperature of the heated target.

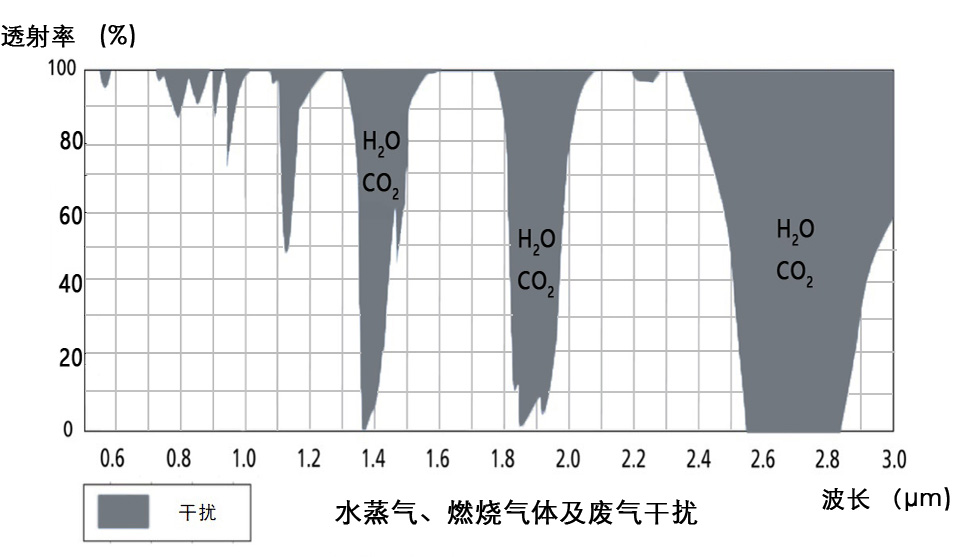

The following picture is a graph of the absorption and penetration wavelengths of water vapor and flame. The gray portion indicates the absorption band of the flame and steam. And the white portion indicates the transmission band of the flame and steam.

In industrial production processes, many large heating equipments are gas heating furnaces, such as rolling steel, coking, rotary furnaces etc.. Let us take the gas heat treatment furnace as example. General equipment is divided into heating zone, heat preservation zone and cooling zone. The narrow-band infrared pyrometers A and the full-radiation infrared pyrometers B are simultaneously aimed at the heat preservation zone. When the combustion gas and the product temperature are the same, take the same value from the readings of the two infrared pyrometers. However, when moving the two infrared pyrometers to the heating zone (the temperature of combustion gas is higher than the product), infrared pyrometers A can measure the true temperature of the product, and the Measurements for full-radiation infrared pyrometers B will be 30 degrees Celsius higher. When moving to the cooling zone, infrared pyrometers A can measure the true temperature of the product, but the Measurements for full-radiation infrared pyrometers B will be 30 degrees Celsius lower. An infrared pyrometer designed with strict wavelength selection can pass through steam, flame and combustion gases to measure the true temperature of the target object.

The difficulty in measuring the temperature of the gas heating furnace is that the measured space has an open flame disturbance. The narrow-band infrared pyrometer developed by Dikai Optoelectronics can overcome this problem. It can achieve accurate measurement of the target being measured without interference from the flame. Especially suitable for coking and gas rolling furnaces.

Advantages of short-wave (0.7-2.6μm) infrared pyrometers:

1. Can realize transmission fiber temperature measurement;

2. Temperature measurement by penetrating glass, steam, water, combustion gas, plasma, and laser beam;

3. Can realize temperature measurement of 100-3500 °C;

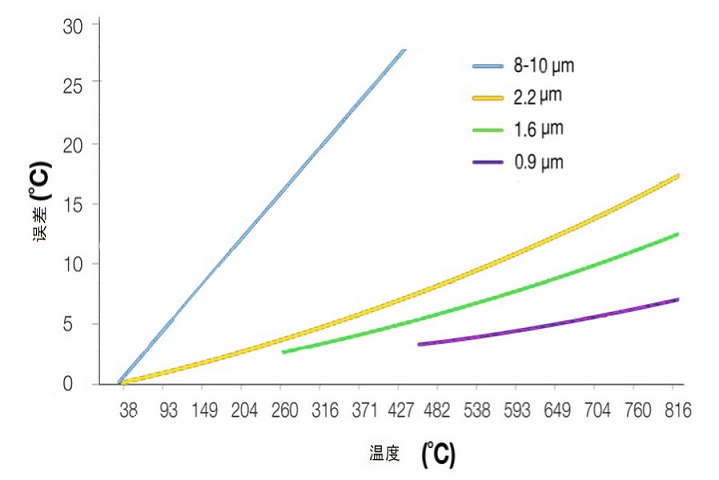

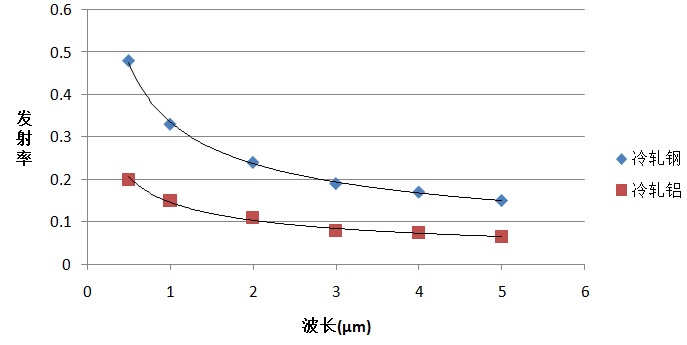

4. Compared with long-wave pyrometers, the effect of emissivity on measurement accuracy is reduced by about 5 to 20 times;

5. Compared with long-wave pyrometers, the energy loss of the optical system is reduced by about 7 to 20 times;

6. Compared with long-wave pyrometers, the requirement for measuring the target size is reduced by about 5 times;

7. Compared with long-wave pyrometers, the aiming difficulty is reduced by about 10 times.

Temperature-wavelength error diagram

Wavelength-emitter ratio diagram

Since many of the available spectral ranges can be used in different conditions, we recommend a personal detailed Consultation before you decide choosing which pyrometer.

The suitable applications for different series of Infrared Pyrometers from Dikai Optoelectronics:

(The following is a general classification. In practical applications, for the same industry or process temperature measurement, it can be further subdivided according to various possible factors. Due to the diverse needs on-site, we only list the product series below, but not the specific Model. If you have any specific requirements, please consult the sales staff of Dikai in detail.)

Routine inspection: DKHIRT portable series

Coke oven temperature measurement: FOT4C

Molten steel measurement: IRPT, DIT-6

Rolling: DIT-6

Heat treatment: IT6, IT8

Gas stove, coal stove: WRIRT (special instructions before ordering, add filter)

Aluminum processing: IT8L (2.2μm)

Copper heat processing: IT8

Other high melting point metals: WRIRT

Chemical industry: IT7

Refractory industry: IT8, WRIRT

Monocrystalline silicon polysilicon, CVD, diamond, special semiconductor materials: DIT-6

Glass and related products: IT7, IT8

Spraying and baking: IT8L (8-14μm)

Laser welding: FOT8L (can be customized for narrow band)

Laser cladding: IT8

Precision Hot Forging: DIT-6

Medium frequency diathermy: IT6, IRPT, DIT-6

High-frequency welded pipe: DIT-6 (add special filter to measure temperature through water)

High frequency welding: FOT8, IT5

Casting: IT8

Kiln: IT6, IT8

Rotary kiln temperature measurement: FOT6

Sintering: IT7 (two-wire pyrometer)

Vacuum heating equipment: DIT-6, WRIRT

Scientific research, special materials: WRIRT

Power inspection: DKLX thermal imaging camera

Fire: DKLT thermal imaging camera

Busbar and cable duct temperature measurement: PD-CWDnK distributed pyrometer

Terminal block, node temperature measurement: PD-GXGS fluorescence pyrometer