In order to achieve stable production, high yield, high quality, low consumption and long service life of the coke oven, the coke cake of each carbonization chamber is required to be uniformly matured in the long direction and the high direction within the prescribed coking time. Therefore, The measurement and control of the coke oven temperature is an important part of ensuring the normal and efficient operation of the coke oven.The coke oven temperature parameters include: straight line temperature, horizontal row temperature, side channel temperature, coke cake center temperature, regenerator top temperature, small flue temperature, roof space temperature, carbonization chamber wall temperature, and cooling temperature.

The number of fire channels in the coke oven combustion chamber is large. In order to uniformly heat and facilitate inspection and control, each fire machine has a fire channel selected on the machine and the focal side. Generally, the temperature of two fire channels is selected to represent the temperature of the machine and the focal side.The temperature measured from these fires is called the straight line temperature. The standard temperature refers to the control value of the average temperature of the machine and the focal side, and is the main temperature index for ensuring the maturity of the coke cake during the coking time.

The temperature of the coke oven fire channel will change with various factors. In order to meet the requirements of uniform heating of the carbonization chambers of the whole furnace, FOT4C temperature measurement system from Dikai Optoelectronics can be directly placed on the top of the furnace to realize the real-time online detection of the vertical fire channel temperature. It replaced the original temperature measurement by the temperature measuring worker. This makes the coke oven heating temperature change from the original monthly average to real-time temperature monitoring.

The traditional measurement method is to measure the straight-through temperature once every 4h. Due to the different time of the fire channel measured by the position, the cooling value of the section fire channel temperature during different commutation periods needs to rely on non-real-time data to intelligently calculate the average furnace temperature of the machine and the focal side.

The temperature of each fire channel in the same combustion chamber is called the horizontal temperature. The width of the carbonization chamber of the top-mounted coke oven is gradually increased from the machine side to the focal side, and the coal loading is gradually increased. In order to ensure that the coke cake matures along the length of the carbonization chamber, The temperature of the fire channel of each combustion chamber should be gradually increased from the lateral side of the machine, which requires that the temperature from the second side of the machine side to the second side of the focal side should rise uniformly.

Obviously, the choice of the standard fire channel, the height of the flame on the machine side, etc. have an effect on the temperature difference between the machine and the focal side.

Coke car and coke cake temperature measurement

Flue temperature measurement

For more information, please contact us!

The value of the coke oven temperature measurement system

1. Reduce labor costs.

2. Real-time multi-point monitoring to improve production efficiency.

3. Improve the automation degree of coking production

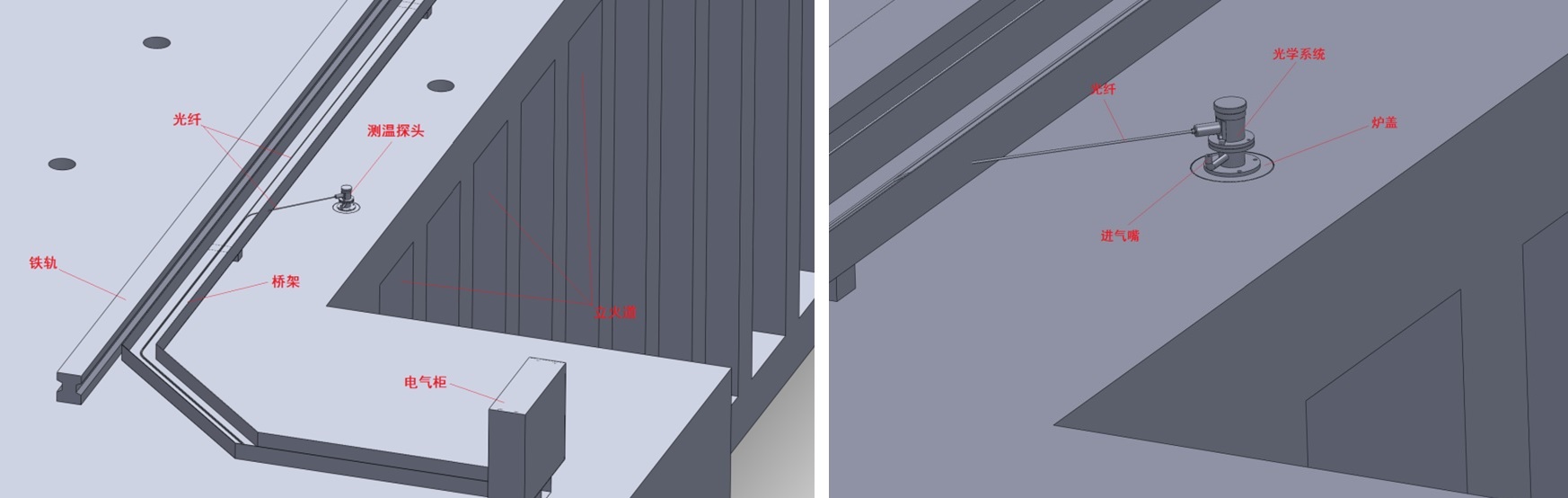

Basic composition of coke oven temperature measurement system

The coke oven temperature measurement system consists of FOT4C fiber optic temperature measurement system, data acquisition software, data relay and power supply.

Site construction diagram

Software interface diagram

Software interface diagram